TyGRe: High added value materials from waste tyre gasification residues

The disposal of waste tyres represents a relevant problem within the waste management strategy of the European Community and, despite the attempts of reusing waste tyre in many different ways, a relevant fraction (nearly 23%) is still landfilled.

Pyrolysis and gasification are a promising way for alternative high-efficiency material and energy production, since both the processes provide a gaseous and a liquid fraction easily usable as fuels or chemical sources. Nevertheless, besides these encouraging preliminary remarks, the experiences on both pilot and industrial scale have shown that without a valuable exploitation of the solid by-product (char), the whole economic balance of the process is not advantageous and therefore the process is not sustainable.

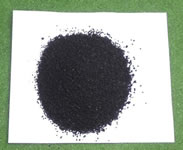

The gasification/pyrolysis treatment of waste tyres, apart from a high hydrogen rich syngas, brings to a very high carbon-rich char fraction, which has been tested in the past as a semi-reinforcing filler for new tyres or as an active carbon. Nevertheless, despite the recent technological advances, it is still unclear whether there is a market demand for this product.

On these bases, the main idea of the proposal consists in redirecting the gasification process towards the material recycling, by coupling a second thermal process, dedicated to the plasma synthesis of silicon carbide, to the preliminary waste tyres gasification.

PROJECT

PROJECT